Product Overview:

Pinch valves, the simplest valve design, include any valve with a flexible elastomer body that can be pinched close to cut off flow, using a mechanism or fluid pressure. They are linear motion valves that can be used to start, stop and throttle media through a system. Pinch valves are low maintenance, low weight, and can be used in systems requiring explosion-proof line closure. While the design of pinch valves provides extensive advantages for use in sterile lines and in situations where product purity is a high priority, these same design features do create some disadvantages. Due to their elastomeric bodies, pinch valves are not viable in situations where the transport media is at a high temperature. They are also not recommended for services that require high-pressure flow, and for use with gases.

Product Features:

1. Advantages

1. Very Clean

2. Excellent drainage

3. Minimal turbulence

4. Low airborne contaminants

5. Low maintenance

6. Low weight

7. Can be used in explosion-proof lines

8. Inexpensive

2. Disadvantages

1. Cannot be used in high temperature applications

2. Cannot be used in high pressure applications

3. Cannot be used with gas media

Method of Control:

1. Pinch valves use a liner motion method of control.

2. The disc is a flexible material liner, similar to a diaphragm.

3. The stem of the pinch valve has a free-moving connection to a moving closure bar, called a compressor, which is located directly above the liner.

4. As the hand wheel is turned, the compressor lowers the liner to squeeze the liner against the bottom support to close the valve.

5. The pressure of the media in the valve can help in starting or stopping the flow.

Function:

Pinch valves can be used for On/Off, as well as throttling services.

Pinch valves are ideal for on/off services because of their straight through design that allows for uninhibited flow. Straight through designs also have very little pressure drop between the inlet and outlet.

The effective throttling range of a pinch valve is usually between 10% and 95% of the rated flow capacity. The best flow control is at the last 50% of the stroke. This is because the smooth walls and resilience of the liner do not provide a significant pressure drop until at least 50% of the stroke has been achieved. To avoid using the ineffective half of the full stroke some pinch valves are designed for maximum opening at 50%. It is not recommended that media with sharp particles are throttled close to shutoff. The particles can scratch the liner, causing grooves that could potentially tear.

Media:

1. Pinch valves can be used for liquid, solid and slurry applications.

2. The valve can effectively control the flow of both abrasives and corrosives, as there is no contact between metal parts and the transport media.

3. Pinch valves have a liner which keeps all moving parts outside of the flow stream so large particulates can be trapped in the seal area of the valve without breaking the seal.

4. Due to the isolation of the valve parts from the media these valves can also be used in applications where corrosion or metal contamination of the fluid, slurries, sand-entrained water systems, sewage treatment, and process food might be a problem.

Note: In liquid applications, the liquid must be kept moving so the displacement of the fluid by the sealing area does not cause additional strain on the liner and cause it to burst.

Looking for ideal Pinch Valves Manufacturer & supplier ? We has a wide selection at great prices to help you get creative. All the Pinch Valve Manufacturer are quality guaranteed. We are China Origin Factory of Pinch Tube Valve. If you have any question, please feel free to contact us.

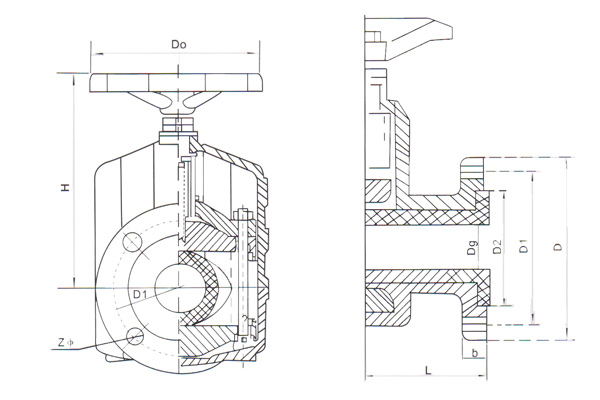

Dimensions:

| ID | Main outling dimensions and connection dimensions | KG | |||||

| L | D | D1 | D2 | b | z-Ф | ||

| 20 | 135 | 105 | 75 | 55 | 16 | 4-14 | 2.5 |

| 25 | 145 | 115 | 85 | 65 | 16 | 4-14 | 3 |

| 32 | 160 | 135 | 100 | 78 | 18 | 4-18 | 4 |

| 40 | 180 | 145 | 110 | 85 | 18 | 4-18 | 6 |

| 50 | 210 | 165 | 125 | 100 | 20 | 4-18 | 7.5 |

| 65 | 250 | 185 | 145 | 120 | 20 | 4-18 | 9.5 |

| 80 | 300 | 190 | 160 | 135 | 22 | 4-18 | 16 |

| 100 | 350 | 215 | 180 | 155 | 22 | 8-18 | 20 |

| 125 | 430 | 245 | 210 | 185 | 25 | 8-18 | 28 |

| 150 | 500 | 280 | 240 | 210 | 25 | 8-23 | 43 |

| 200 | 650 | 335 | 295 | 265 | 32 | 8-23 | 80 |

| 250 | 800 | 390 | 350 | 31 | 32 | 12-23 | |

| 300 | 950 | 562 | 445 | 400 | 32 | 12-23 | |

| 400 | 1100 | 565 | 515 | 460 | 32 | 16-25 | |

| 450 | 1120 | 640 | 585 | 540 | 35 | 20-28 | |

| 500 | 1235 | 705 | 650 | 600 | 38 | 20-28 | |

- Previous:No record

- Flange Air Pinch Valve Next:

Contact us

Tel:

+86 18703845698

ailsa@gyldt.com