Stainless Steel Corrugated Expansion Joints are stainless steel corrugation designed contributing to the solution of piping system problems. It is used to absorb pipe movements, relieve stress.

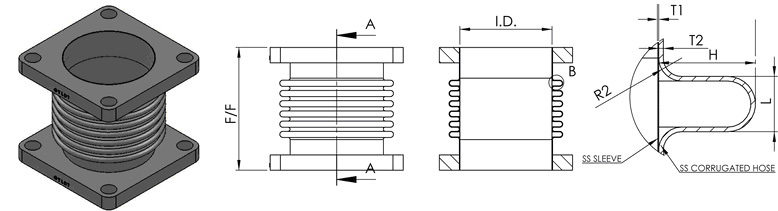

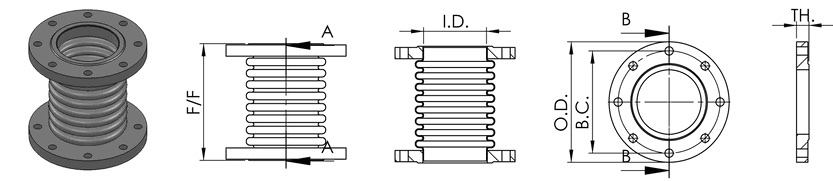

Stainless Steel Corrugated Expansion Joint

Stainless Steel Corrugated Expansion Joints are stainless steel corrugation designed contributing to the solution of piping system problems. It is used to absorb pipe movements, relieve stress, reduce system noise/vibration, compensate for misalignment/offset and protect rotating mechanical equipment against start-up surge forces. Assemblies are designed for both high and low temperatures.

Features and Benefit:

·Compensate misalignment, absorbs vibrations in the pipeline

·Directional Movement Absorbing

·Wide Size and Service Range

·For both high and low temperatures

·Materials available upon request

Looking for ideal Stainless Steel Corrugated Expansion Joint manufacturer & supplier ? We has a wide selection at great prices to help you get creative. All the Steel Expansion Joint are quality guaranteed. We are China Origin Factory of Steel Twin Expansion Joint. If you have any question, please feel free to contact us.

Features and Benefit:

·Compensate misalignment, absorbs vibrations in the pipeline

·Directional Movement Absorbing

·Wide Size and Service Range

·For both high and low temperatures

·Materials available upon request

Looking for ideal Stainless Steel Corrugated Expansion Joint manufacturer & supplier ? We has a wide selection at great prices to help you get creative. All the Steel Expansion Joint are quality guaranteed. We are China Origin Factory of Steel Twin Expansion Joint. If you have any question, please feel free to contact us.

Specifications

|

Nominal diameter:

|

DN15mm to DN3000mm, special design available

|

|

Maximum working pressure:

|

4.0 Mpa

|

|

Vacuum KPa(mmHg)

|

44.9(350)

|

|

Operating temperature:

|

-60℃-280℃

|

|

Corrosion resistance

|

Excellent

|

|

Applicable media

|

Sea water, drinking water, exhaust, industrial sewage.

|

Design:

Data Sheet:

|

SIZE

|

WORKING PRESSURE(BAR)

|

CORRUGATIONS

|

Prox. Weight without Flanges (kg)

|

||||

|

I.D.×F/F

|

2.5

|

6

|

10

|

16

|

25

|

||

|

Axial Offset(mm)/Spring Rate(N/mm)

|

|||||||

|

32×110

|

|

22/26

|

20/26

|

18/63

|

15/98

|

8

|

0.35

|

|

40×130

|

|

22/44

|

20/44

|

18/89

|

15/106

|

8

|

0.52

|

|

50×150

|

|

22/51

|

20/70

|

18/70

|

15/138

|

8

|

0.75

|

|

65×170

|

|

30/35

|

26/44

|

22/55

|

19/68

|

8

|

1.1

|

|

80×200

|

|

36/26

|

34/33

|

28/41

|

24/54

|

8

|

1.6

|

|

100×220

|

|

45/60

|

40/75

|

35/93

|

29/117

|

8

|

2.2

|

|

125×240

|

|

77/29

|

66/36

|

58/45

|

50/56

|

8

|

3.0

|

|

200×280

|

|

65/44

|

59/52

|

53/58

|

48/78

|

8

|

5.6

|

|

250×280

|

|

65/34

|

59/42

|

52/45

|

47/55

|

6

|

7.0

|

|

250×340

|

|

97/21

|

87/35

|

79/39

|

71/47

|

8

|

8.5

|

|

300×330

|

|

65/55

|

59/59

|

52/65

|

47/71

|

6

|

9.9

|

|

300×380

|

|

97/35

|

87/37

|

79/41

|

71/45

|

8

|

11

|

|

350×360

|

|

65/62

|

59/67

|

52/74

|

47/81

|

6

|

13

|

|

350×420

|

|

97/41

|

87/44

|

79/48

|

71/47

|

8

|

15

|

|

400×360

|

|

65/58

|

56/62

|

52/68

|

47/75

|

6

|

14

|

|

400×420

|

|

97/39

|

87/43

|

79/47

|

71/52

|

8

|

17

|

|

450×360

|

|

97/35

|

87/37

|

79/41

|

71/45

|

6

|

16

|

|

450×460

|

|

145/22

|

131/23

|

118/25

|

106/28

|

8

|

21

|

|

500×450

|

|

97/64

|

87/68

|

79/75

|

71/82

|

6

|

23

|

|

500×520

|

|

145/37

|

131/49

|

118/43

|

106/48

|

8

|

26

|

|

600×480

|

|

97/80

|

87/85

|

79/94

|

71/103

|

6

|

29

|

|

600×560

|

|

145/45

|

131/49

|

118/53

|

106/60

|

8

|

34

|

|

700×400

|

|

97/72

|

87/77

|

79/85

|

71/95

|

4

|

28

|

|

700×520

|

|

145/45

|

131/49

|

118/53

|

106/60

|

6

|

36

|

|

800×410

|

|

108/95

|

102/102

|

94/112

|

82/123

|

4

|

33

|

|

800×520

|

|

164/72

|

156/77

|

144/85

|

125/93

|

6

|

42

|

|

900×410

|

|

108/90

|

102/97

|

94/107

|

82/117

|

4

|

37

|

|

900×520

|

|

164/65

|

156/69

|

144/76

|

125/84

|

6

|

47

|

|

1000×410

|

|

108/98

|

102/105

|

94/116

|

|

4

|

41

|

|

1000×520

|

|

164/65

|

156/71

|

144/81

|

|

6

|

52

|

|

1100×670

|

77/395

|

44/1703

|

34/4408

|

32/4473

|

|

4

|

74

|

|

1100×790

|

116/263

|

65/1135

|

51/2938

|

47/2982

|

|

6

|

87

|

|

1200×670

|

76/425

|

43/1843

|

34/4770

|

32/4843

|

|

4

|

80

|

|

1200×800

|

114/283

|

65/1228

|

51/3182

|

47/3229

|

|

6

|

96

|

|

1300×670

|

74/455

|

43/1985

|

34/5139

|

31/5215

|

|

4

|

87

|

|

1300×800

|

113/30

|

64/1323

|

50/3426

|

47/3477

|

|

6

|

104

|

|

1400×670

|

74/485

|

42/2128

|

34/5506

|

31/5587

|

|

4

|

94

|

|

1400×800

|

111/323

|

64/1416

|

50/3671

|

47/3725

|

|

6

|

112

|

|

1500×670

|

73/515

|

42/2270

|

33/5874

|

31/5961

|

|

4

|

101

|

|

1500×800

|

110/343

|

641513

|

50/3916

|

46/3974

|

|

6

|

120

|

|

1600×700

|

72/545

|

42/2410

|

33/6242

|

|

|

4

|

112

|

|

1600×800

|

108/363

|

64/160

|

50/4161

|

|

|

6

|

128

|

|

1700×700

|

71/575

|

42/2553

|

33/6611

|

|

|

4

|

119

|

|

1700×800

|

107/383

|

63/1702

|

50/4407

|

|

|

6

|

136

|

|

1800×700

|

71/605

|

35/5218

|

33/6981

|

|

|

4

|

126

|

|

1800×800

|

106/403

|

53/3478

|

50/4654

|

|

|

6

|

144

|

|

1900×700

|

70/635

|

35/5498

|

33/7345

|

|

|

4

|

133

|

|

1900×800

|

106/426

|

53/5662

|

50/4900

|

|

|

6

|

152

|

|

2000×850

|

66/943

|

39/4173

|

36/5726

|

|

|

4

|

170

|

|

2000×900

|

88/708

|

52/3130

|

48/4291

|

|

|

6

|

180

|

1. The weight is approximate without welding flange

2. Floating flange can be provided

3. Connection flange can be drilled as request

4. The material of flange is carbon steel, painted, other material available up on request

5. The material of bellows is stainless steel 304, other material available upon request

6. The material of braid is stainless steel 304, other material available upon request

- Previous:Steel Expansion Joint

- No record Next:

Contact us

Tel:

+86 18703845698

ailsa@gyldt.com