The dismantling joint is designed to be the final closing piece in the pipe network, to ease the assembling and disassembling for later maintenance of a pump or valve.

Dismantling Joint

The dismantling joint is designed to be the final closing piece in the pipe network, to ease the assembling and disassembling for later maintenance of a pump or valve. A standard

adjusting range of 50mm on length and a small lateral and angular misalignment can be accommodated. This adjustability of the dismantling joint facilitates for easy removal of

pumps and valves in circumstances of inspection, maintenance or replacement.

Features and Benefit:

·Compensate for differences in flange to flange distance

·Simplify the installation of pipelines

·Integrate a valve or pump into a flanged pipe network

·Flange connection, flange drilling can base on DIN PN6/16/25, ANSI CLASS150/300, JIS, EN, etc

·Reduce assembling time

·Dismantle for service, inspection and maintenance

·Epoxy powder coating and bolting made of steel

·Drinking water approved

Looking for ideal DI Dismantling Joint Manufacturer & supplier ? We has a wide selection at great prices to help you get creative. All the DI Dismantling Joint are quality guaranteed. We are China Origin Factory of DI Dismantling Joint. If you have any question, please feel free to contact us.

Specifications

| Nominal diameter: | DN80mm to DN3000mm |

| Maximum working pressure: | 4.0 Mpa |

| Vacuum KPa(mmHg) | 44.9(350) |

| Operating temperature: | -20℃-80℃ |

| Corrosion resistance | Good |

| Applicable media | Sea water, drinking water, slurry, industrial sewage. |

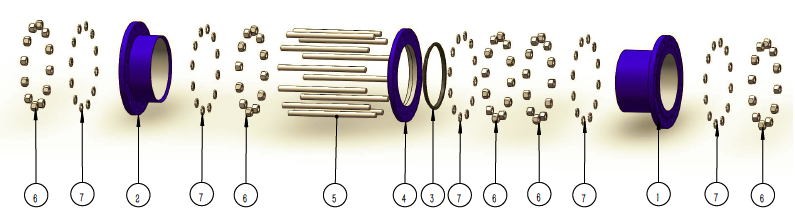

Components/Materials/Functions

| No. | Components | Materials |

| 1 | Long Piece | SS304, SS316, SS321 |

| 2 | Short Piece | SS304, SS316, SS321 |

| 3 | Gasket | EPDM, NBR |

| 4 | Gland | SS304, SS316, SS321 |

| 5 | Stud | SS304, SS316, SS321 |

| 6 | Nut | SS304, SS316, SS321 |

| 7 | Wisher | SS304, SS316, SS321 |

|

Note: · Flanges are according to DIN PN16, ANSI/JIS/EN standard can be supplied upon request. · Design Pressure: 16 bar. · Rubber: EPDM, NBR, NEOPRENE or upon request. · Materials are various to meet per requirement. |

||

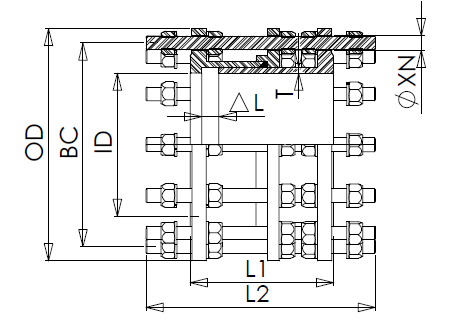

Data Sheet

| DN | ID | OD | BC | L1 | L2 | d | N | T | ΔL |

| 80 | 80 | 160 | 200 | 200 | 310 | 16 | 8 | 7.0 | 40 |

| 100 | 100 | 180 | 220 | 200 | 310 | 16 | 8 | 7.2 | 40 |

| 125 | 125 | 210 | 250 | 200 | 310 | 16 | 8 | 7.5 | 40 |

| 150 | 150 | 240 | 285 | 200 | 320 | 20 | 8 | 7.8 | 40 |

| 200 | 200 | 295 | 340 | 220 | 340 | 20 | 12 | 8.4 | 40 |

| 250 | 250 | 355 | 400 | 230 | 370 | 24 | 12 | 9.0 | 40 |

| 300 | 300 | 410 | 455 | 250 | 410 | 24 | 12 | 9.6 | 50 |

| 350 | 350 | 470 | 520 | 260 | 410 | 24 | 16 | 10.2 | 50 |

| 400 | 400 | 525 | 580 | 270 | 430 | 27 | 16 | 10.8 | 50 |

| 450 | 450 | 585 | 640 | 270 | 430 | 27 | 20 | 11.4 | 50 |

| 500 | 500 | 650 | 715 | 280 | 440 | 30 | 20 | 12.0 | 50 |

| 600 | 600 | 770 | 840 | 300 | 480 | 33 | 20 | 13.2 | 50 |

| 700 | 700 | 840 | 910 | 300 | 480 | 33 | 24 | 14.4 | 60 |

| 800 | 800 | 950 | 1025 | 320 | 520 | 36 | 24 | 15.6 | 60 |

| 900 | 900 | 1050 | 1125 | 320 | 520 | 36 | 28 | 16.8 | 60 |

| 1000 | 1000 | 1170 | 1255 | 340 | 560 | 39 | 28 | 18.0 | 60 |

| 1100 | 1100 | 1270 | 1355 | 340 | 560 | 39 | 32 | 19.2 | 60 |

| 1200 | 1200 | 1390 | 1485 | 360 | 600 | 45 | 32 | 20.4 | 60 |

| 1400 | 1400 | 1590 | 1685 | 380 | 630 | 45 | 36 | 22.8 | 60 |

| 1500 | 1500 | 1710 | 1820 | 400 | 665 | 52 | 36 | 23.0 | 60 |

| 1600 | 1600 | 1820 | 1930 | 400 | 700 | 52 | 40 | 25.2 | 60 |

| 1800 | 1800 | 2020 | 2130 | 420 | 730 | 52 | 44 | 27.6 | 60 |

| 2000 | 2000 | 2230 | 2345 | 440 | 730 | 56 | 48 | 30.0 | 60 |

| 2200 | 2200 | 2440 | 2555 | 450 | 750 | 56 | 52 | 32.4 | 60 |

| 2400 | 2400 | 2650 | 2765 | 460 | 770 | 56 | 56 | 34.8 | 60 |

| 2600 | 2600 | 2850 | 2965 | 500 | 800 | 56 | 60 | 37.2 | 80 |

- Previous:Stainless Steel Dismantling Joint

- Flexible Coupling Next:

Contact us

Tel:

+86 18703845698

ailsa@gyldt.com